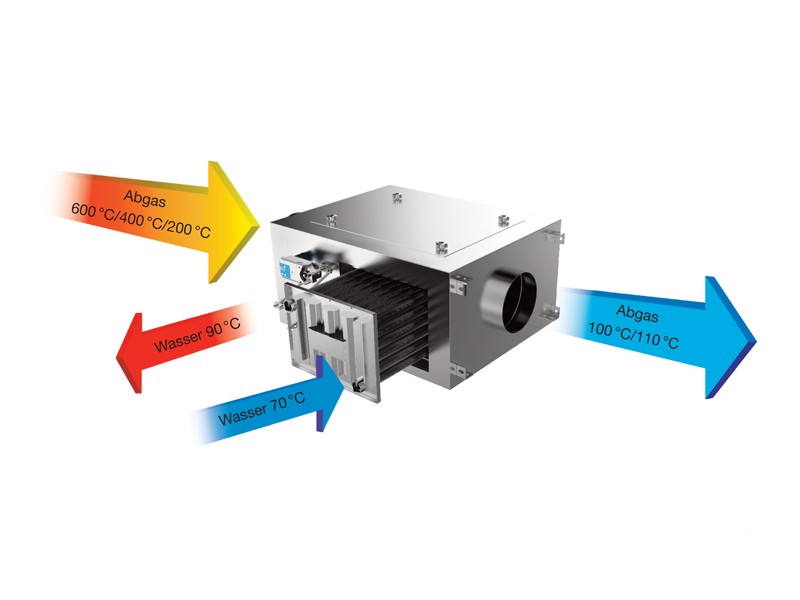

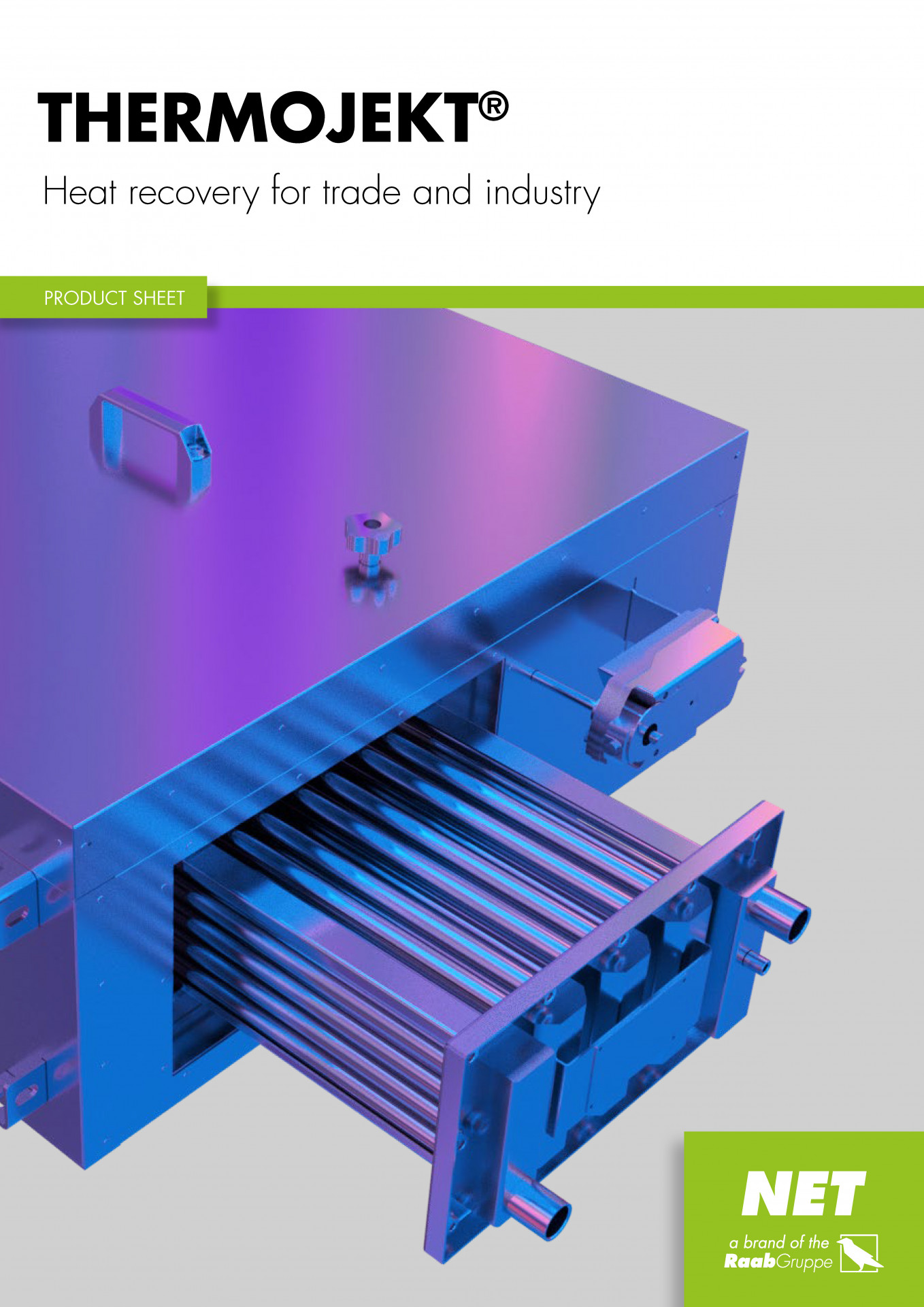

Here, the flue gas heat exchanger transfers the waste heat of the flue gas to the water that flows through the heat exchanger’s register.

This heats the water and cools the flue gas. The heat recovered from the flue gas can be used elsewhere. This results in considerable energy cost savings, especially in energy-intensive industrial operations.

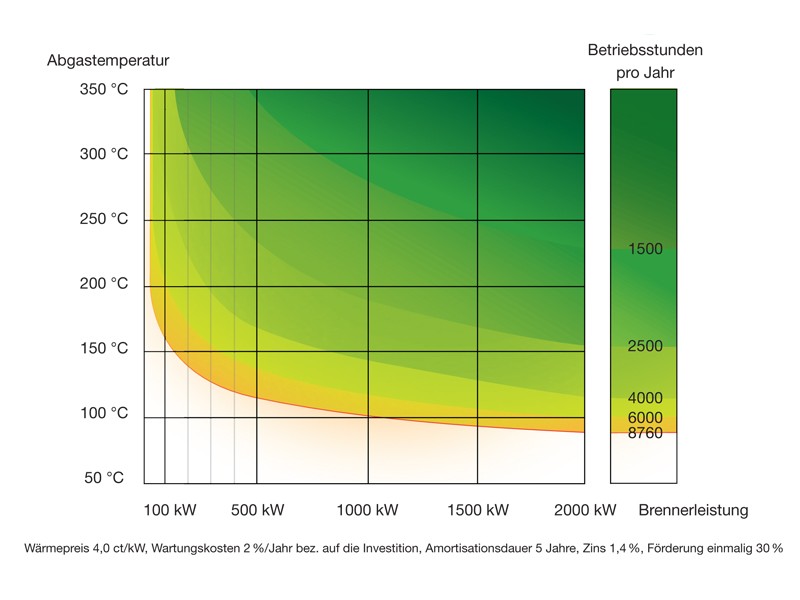

When does heat recovery make sense?

Today, rising energy prices allow for shorter and shorter payback periods.

Flue gas temperature, burner output and operating hours determine how long the amortisation takes.

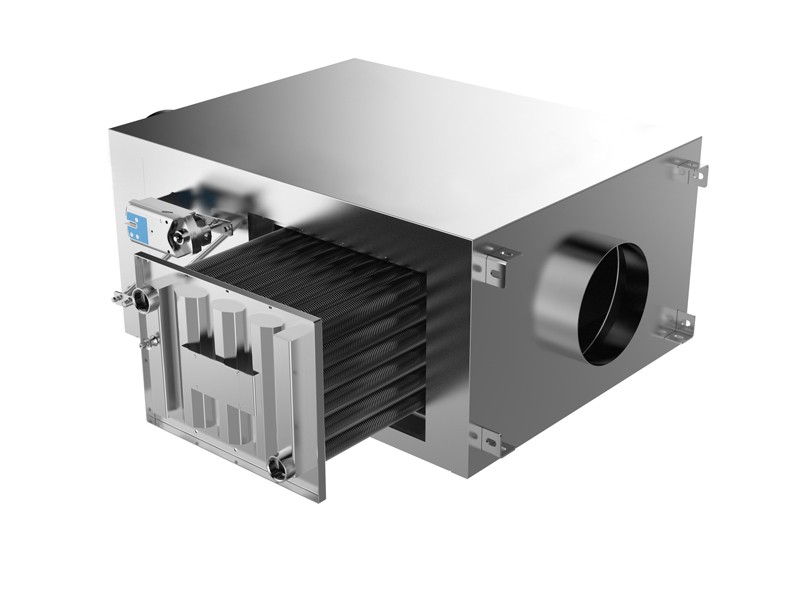

Extendable register

The extendable register allows for easy and thorough cleaning.

This is necessary if deposits have formed on the heat exchanger surfaces after prolonged operation. During cleaning, the housing remains fixed.

The register can be easily pulled out after loosening a few screws.

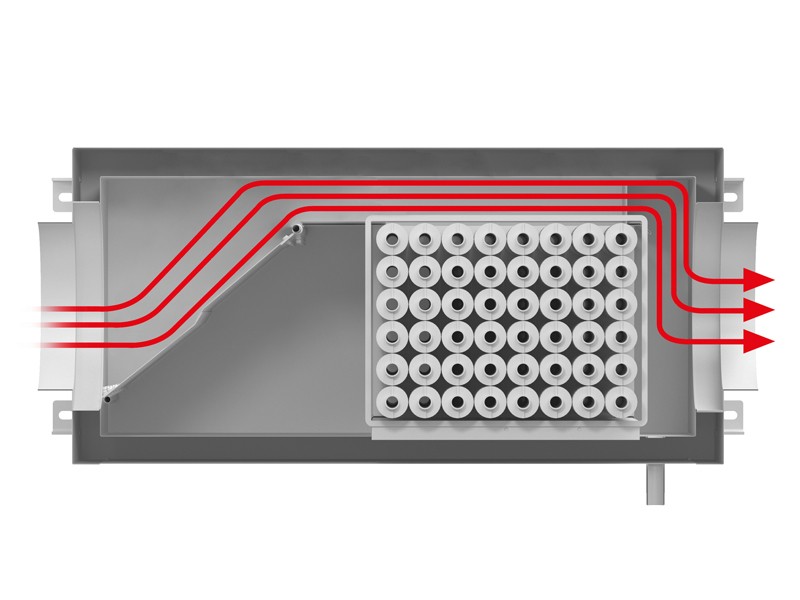

Internal bypass solution

If heat is not required at times, the hot air or flue gases can be routed past the register through the internal bypass.

The bypass dampers in the heat exchanger are moved by a maintenance-free actuator outside the casing.

These dampers are controlled by a thermostat or a controller with a temperature sensor at the heat storage tank and the heat exchanger.

External bypass solutionFor applications with extremely high temperatures we offer an alternative with an external bypass solution. The hot flue or exhaust gases are led past the register of the heat exchanger ”Thermojekt ® R“.

This completely prevents any vaporization of the carrier medium inside the registers due to residual heat transfer.

It also reduces the transfer of heat from the bypass to the register to a minimum.

These features ( extendable register and bypass solutions) can be inserted/added to the descriptions of the individual types (R,RB,G…).

In energy-intensive commercial and industrial operations, heat recovery can save resources and associated costs. These include, above all:

- Large bakeries and other manufacturing companies from the food industry

- Hardening shops

- Foundries

- Metalworking companies

- Company from the field of plastics manufacturing

- Various plants with thermal processes

- Companies that burn industrial solvents

Larger companies are even legally obliged to reduce primary energy consumption through energy audits and energy management systems. Although these regulations do not yet apply to small and medium-sized enterprises (SMEs), competitive advantages can be achieved through lower production costs by using a heat recovery system.

Regardless of the size of the company, the use of heat recovery systems means:

- Lower energy costs

- More independence from external energy supply

- Reduction of emissions

- Less effort for heating and recooling systems

- Funding opportunities and tax incentives

- Image improvement

Here you have the possibility to download the brochures you are interested in as PDF files.