EW – Single-walled stainless steel flue gas system, the specialist for modernization

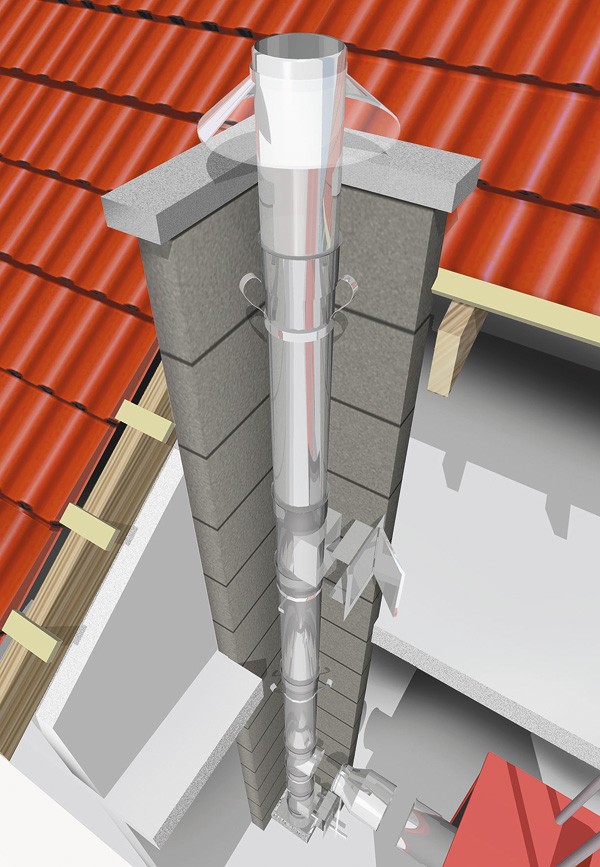

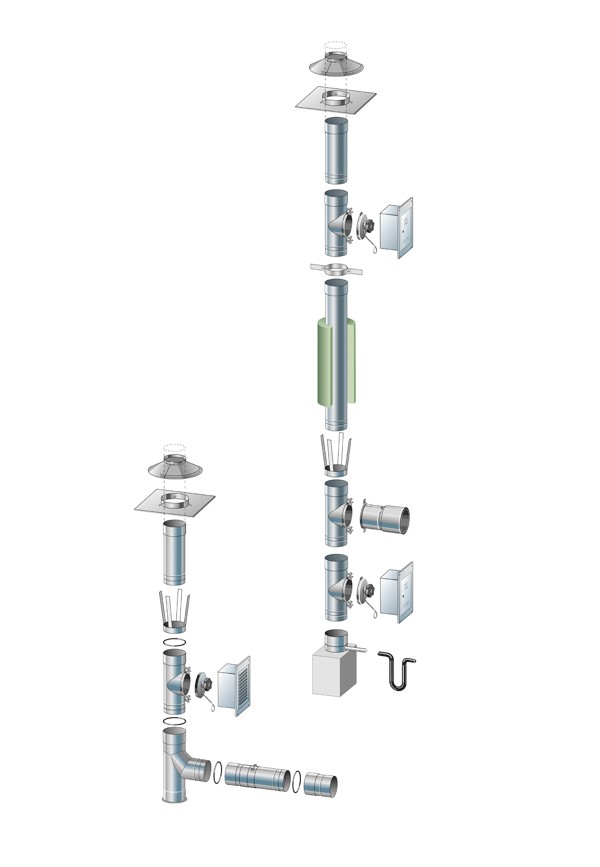

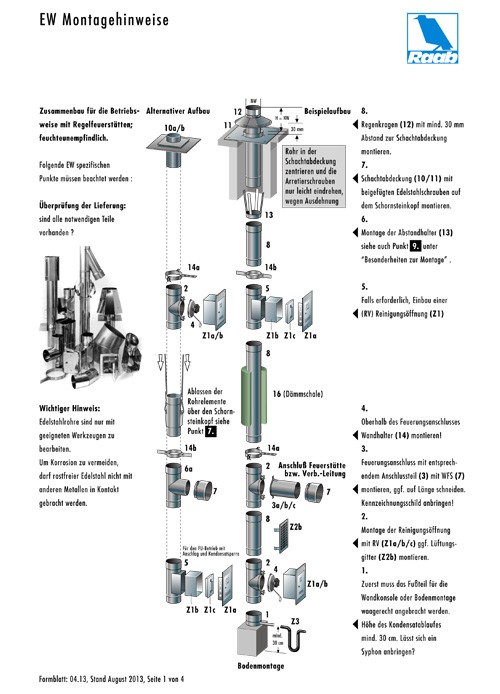

The single-walled, humidity-insensitive Raab EW system is the proven system for installation in existing chimneys when converting to new heat generators. In addition to chimney refurbishment, it is also ideally suited for installation in Raab lightweight shafts for new flue gas systems to be constructed in the building. In addition, Raab EW can be used for connecting pipes.

A wide variety of fireplaces can be connected, whether chimney or tiled stoves, boilers for oil, gas, wood, wood pellets or condensing boilers for oil or gas. As a WPG version in material 1.4539 for wood logs, wood pellets and wood chips, the EW system is even approved for humid operation after a possible soot fire.

The easy-to-install system with 80 mm long plug-connection has high longitudinal stability and, thanks to its small external dimensions, allows installation even in narrow existing chimneys. For operation in overpressure different seals are available depending on the application.

Raab EW is available in wall thicknesses of 0.6 mm and 1.0 mm and can be combined with the flexible flue gas systems. A comprehensive range of accessories with matching flue gas silencers, adapters for Kutzner + Weber draught regulators and fine dust particle separators round off the product range.

EW at a glance

| Certification | DOP-No. 0432-CPR-00117-10/110 |

| T120 P1 WO | up to 120 °C flue gas temperature, positive pressure 200 Pa, humid operation oil/gas – with EPDM seal |

| T200 H1 WO | up to 200 °C flue gas temperature, overpressure 5,000 Pa, humid operation, oil/gas – with FKM seal |

| T400 N1 WO | up to 400 °C flue gas temperature, negative pressure, humid operation, oil/gas |

| T600 N1 DG | up to 600 °C flue gas temperature, negative pressure, dry operation, soot fire resistant, oil/gas/solid fuels |

| T600 N1 WG | up to 600 °C flue gas temperature, negative pressure, humid operation, soot fire resistant, oil/gas/solid fuels |

Attention: Version P1, H1 with lip seal only in 0.6 mm if necessary deviating specifications see individual components

Material and designs

- High quality stainless steel 1.4404

- High-gloss surface, low contamination

- WPG 1.4539, high temperature material 1.4828 on request

- Material thickness 0.6 and 1.0 mm

- Inside diameter 80 – 600 mm round, oval as special design

- Tubes TIG/laser butt welded

- Moulded parts drawn or welded and passivated using the high-pressure pressing process

- Flexible connection technology: Functional and can be shortened on site. Easily adaptable to difficult conditions due to component diversity and ready for immediate use.

- Delivery forms: Round cross-section as standard, also available as oval version for confined spaces.

- High-quality materials: In addition to state-of-the-art production methods, decisive for the longevity of the system and high corrosion resistance.

- High quality: CE declaration of performance with voluntary external monitoring according to System 2+. Certified production according to DIN EN ISO 9001.

- Fireplaces for oil, gas, solid fuels, wood, wood chips, wood pellets

- Low temperature and condensing boilers

- Flue gas temperatures up to 600 °C, soot fire resistant

- Installation with or without heat insulation

- Dry and humid (FU) operation mode

- Negative pressure or positive pressure up to 200 Pa with seal

- Single and multiple assignment, connection pipes

- Room air dependent or room air independent in the shaft (LAS)

- Cross-section reduction of existing installations