Function and mode of operation

Function and mode of operation

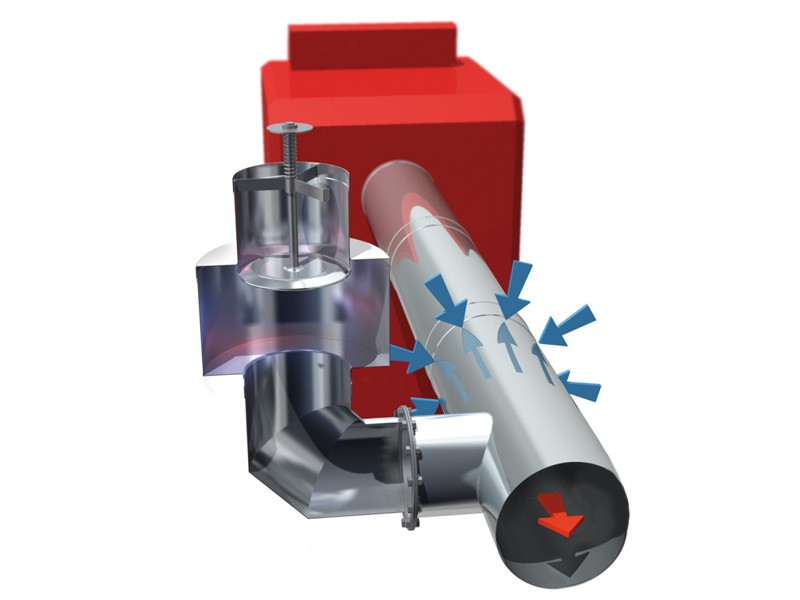

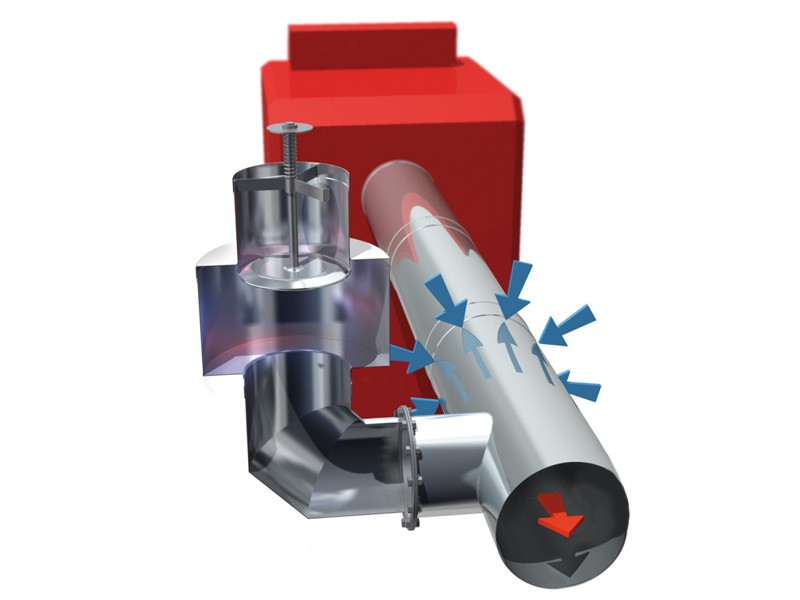

The implosion damper is used for fireplaces that are operated in positive and negative pressure so that no flue gas can escape when the fireplace is operated as intended.

During normal, trouble-free operation, the spring keeps the cover plate closed. If the combustion air damper on the burner is closed due to a power failure, the chimney can no longer draw in air via the boiler. The “missing” air now flows in via the implosion damper. This prevents the so-called Joukowski impact by immediately opening the cover plate.

Practical example: If, for example, the supply air is cut off from the chimney during a sudden power failure, the high negative pressure in the chimney can cause the connecting pipe to contract and deform. The negative pressure can be so strong that the flue gas pipe collapses and the system is irreparably destroyed. Since the stall is instantaneous, the implosion damper must open very quickly to allow air to flow into the chimney. Depending on the system capacity, several of these dampers must be installed.

If the boiler starts up again and/or the vacuum is released, the flap closes automatically due to the spring action. The plant can resume normal operation.

Advantages and solutions

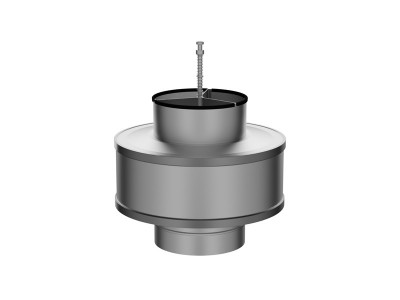

- The implosion damper IK250 is intended for mounting in the connecting line

- The assembly takes place by means of a T-piece

- The IK250 can be mounted in vertical or horizontal pipe

- The kit may have to be dimensionally adapted to the respective connecting line

- The installation is intended for chimneys in negative and positive pressure operation

- Suitable for all fuels