“Late at night and early in the morning – long live the alluvial stone industry.”

This was the motto under which Paul Raab founded his company, the “Neuwieder Schwemmstein- und Zementwarenfabrik Paul Raab” in 1898. Since then, the company has continuously developed and gained a leading position in the field of chimney and flue gas systems.

2023

The Raab Group celebrates the 125th anniversary of Joseph Raab GmbH & Cie. KG in Luckenau.

The Raab Group celebrates the 125th anniversary of Joseph Raab GmbH & Cie. KG in Luckenau.

2023

The filter attachment for draught regulators is presented.

The filter attachment for draught regulators is presented.

2022

![]()

The corporate identity of the Raab Group undergoes a revision. After the purchase of Kutzner + Weber GmbH and NET – Neue Energie-Technik GmbH, the logos remained unchanged for many years. Now the group idea is coming more to the centre of attention.

2020

Rolf Wagenfeld, Managing Partner of the Raab Group, hands over overall sales and marketing management as well as product management to Alexander Root, who becomes Deputy Managing Director in the Raab Group.

2020

The fine dust particle separators of the Airjekt 1 model series are presented. Die Feinstaubabscheider der Modellreihe Airjekt 1 werden vorgestellt.

The fine dust particle separators of the Airjekt 1 model series are presented. Die Feinstaubabscheider der Modellreihe Airjekt 1 werden vorgestellt.

2019

The draught regulators DrafBox and DraftBox light are presented.

The draught regulators DrafBox and DraftBox light are presented.

2017

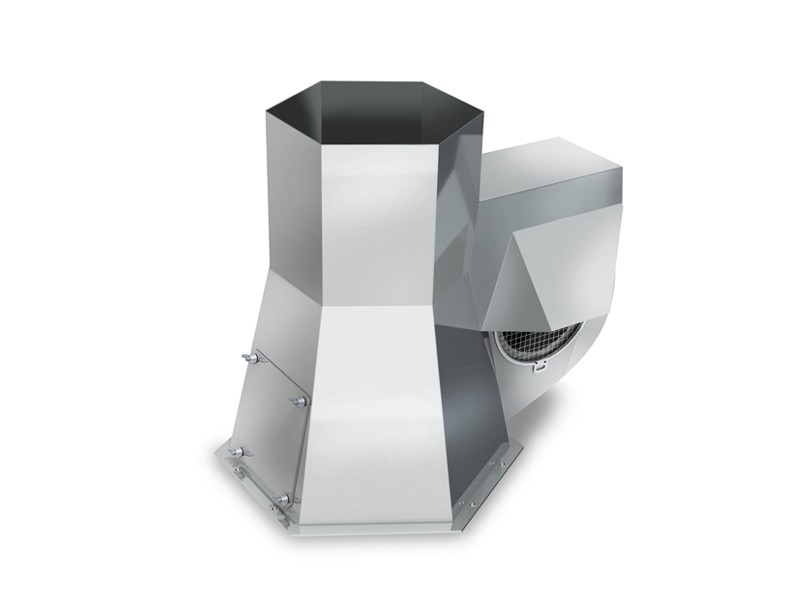

The Linejekt industrial fan for commercial and industrial installations complements the chimney fan portfolio.

The Linejekt industrial fan for commercial and industrial installations complements the chimney fan portfolio.

Exhaust gas switches are presented on the market.

2015

The Raab Group is expanding its product range through the acquisition of a heat recovery specialist: NET New Energy-Technology GmbH from Puchheim near Munich has been active in the heat exchanger business for more than 20 years and brings with it industry expertise in the project planning, construction and servicing of heat recovery systems.

The Raab Group is expanding its product range through the acquisition of a heat recovery specialist: NET New Energy-Technology GmbH from Puchheim near Munich has been active in the heat exchanger business for more than 20 years and brings with it industry expertise in the project planning, construction and servicing of heat recovery systems.

2015

The Airjekt 1 fine dust particle separator is presented at the ISH.

The Airjekt 1 fine dust particle separator is presented at the ISH.

The AirSpeedy chimney fan for stoves and heating inserts in the low output range is presented.

2013

The Diajekt chimney fan for industrial and commercial facilities is presented.

The Diajekt chimney fan for industrial and commercial facilities is presented.

The IK 250 implosion damper is launched on the market.

2010

Rolf Wagenfeld takes over the management of the Raab Group

Rolf Wagenfeld takes over the management of the Raab Group

Born in Bremen, he has known the Raab Group since 2001 as a member of the advisory board. From 2007 he held the position of Vice Chairman of the Advisory Board, and since 2009 the position of Chairman of the Advisory Board.

2010

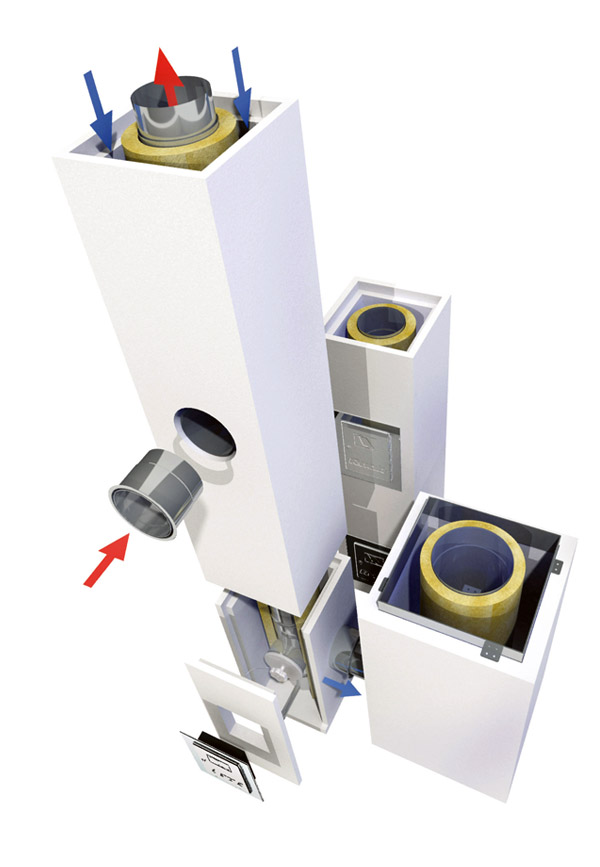

KW introduces the first chimney fan model Injekt for wood-burning stoves and lays the foundation stone for the chimney fan range.

KW introduces the first chimney fan model Injekt for wood-burning stoves and lays the foundation stone for the chimney fan range.

The motorised LAS exhaust flaps are presented.

2009

Establishment and expansion of B2B business.

2008

Further centralization measures are being implemented to increase efficiency, expand our market share and increase sales.

2007

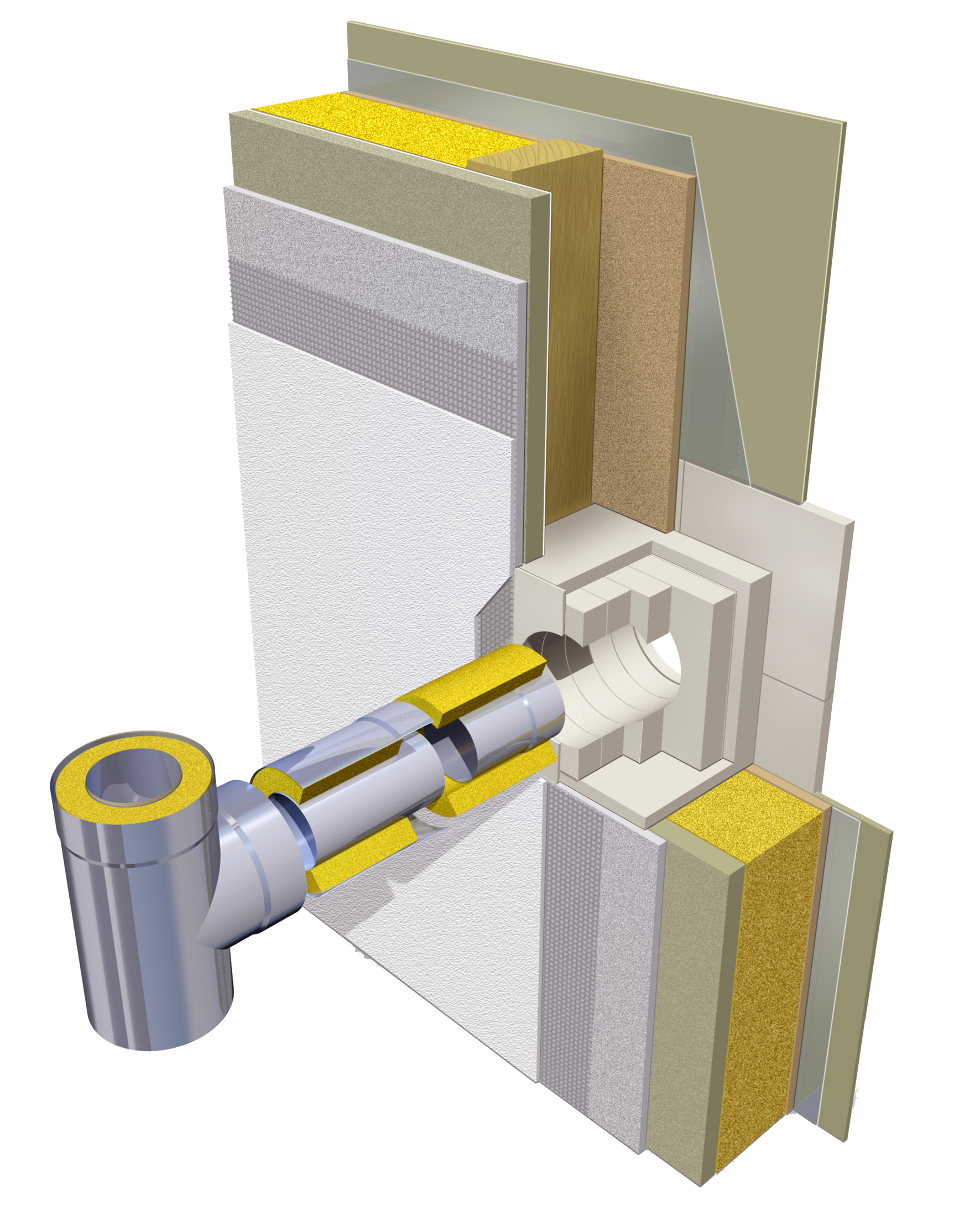

Development of the Raab wall, ceiling and roof bushing, the first tested fire protection element developed on the Raab test stand in Neuwied – a true bestseller with record numbers in all sales channels.

Approval of the highly corrosion-resistant flue gas systems WPG for EW, DW, EW-Alkon and DW-Alkon, these are especially suitable for biomass combustion.

Installation of a new production line for double-walled stainless steel pipes in Neuwied.

The newly established competence centre for project business and large-scale plants in Luckenau enables the production of technically demanding projects in the industrial and municipal sectors.

2006

Proschorn Hungária Kft becomes a subsidiary of the Raab Group.

2005

Conversion of J. Raab AG, Luckenau into J. Raab GmbH, Luckenau.

Conversion of J. Raab AG, Luckenau into J. Raab GmbH, Luckenau.

The product range of lightweight chimneys is extended by the multi-shaft LB LAS-FB, which was particularly important for chimneys that are independent of room air.

The Raab nozzle EN Plus receives the certificate as a tested wind attachment

2005

Marketing and further development of the Zumikron fine dust particle separator from the Rüegg company in Switzerland, entry into the distribution of particle separators for flue gas cleaning.

2004

Concentration of the divisions on the core competence of exhaust systems and exhaust technology. Sale of the grinding and dosing plant division to the Quickmix Group.

2003

The DW-Alkon cleaning opening receives the Design+ award at the ISH.

The DW-Alkon cleaning opening receives the Design+ award at the ISH.

Product expansion in the area of plaster and mortar products through special solutions. Addition of new lightweight shafts to the flue gas system range.

2002

Expansion of the range of services in the lightweight sector to include solid roof elements.

2002

Modernization and adaptation of the flue gas dampers program. Development of further markets abroad.

2001

The production of hollow and solid planks is discontinued in favour of the more modern lightweight concrete prefabricated elements.

2001

Development of special silencer solutions in licence partnership with the Fraunhofer Institute for Building Physics (IBP) in Stuttgart and Servo-Instuments (SID). Start of development work on integrated solutions for the boiler and flue gas industry, acquisition of licence to develop active silencers.

2000

Conversion of J. Raab GmbH & Cie. KG, Luckenau, into J. Raab AG, Luckenau, Germany.

1999

Certificate for a QM system of the DVGM/VDE of the company Kutzner + Weber according to DIN EN 46001 MPG.

Product line Alkon is supplemented with the double-walled system DW-Alkon.

1999

Specialization in the field of flue gas noise, further development of solutions for the market.

1998

Commissioning of one of the most modern pallet circulation systems for the production of precast lightweight concrete parts in Neuwied.

1997

Takeover of Kutzner + Weber, based in Maisach, Germany, and addition of flue gas technology to the product range.

Takeover of Kutzner + Weber, based in Maisach, Germany, and addition of flue gas technology to the product range.

Certificate of the Material Testing Office for a QM system of Joseph Raab GmbH & Cie. KG according to DIN EN ISO 9001.

1993

The services of the Bekotec company are discontinued.

1991

Start of production at the new plant in Luckenau

Start of production at the new plant in Luckenau

1990

The investment in a new production facility in Sachsen-Anhalt with state-of-the-art production technology in the stainless steel sector.

1989 - 1996

Development and distribution of diverse solutions for the boiler industry, as well as function-enhancing and energy-saving products for heating and flue gas technology.

1988

Introduction of the first flue gas silencer program.

1987

Acquisition of the company Servo Instruments Deutschland SID and thus expansion of the flue gas dampers program.

1985

Expansion of production to include stainless steel and lightweight chimneys in system construction

Expansion of production to include stainless steel and lightweight chimneys in system construction

In the following years, the area of chimney elements was continuously expanded.

1985

Development and production of KW draught regulators.

1984

In order to expand further in the area of chimney tops, complementary mortar products were added to the production range.

1983

Production of concrete chimney tops.

Adjustment of the production of planters.

Foundation of the company Bekotec which deals with services related to concrete repair.

1981

Relocation of the company to the new company building in Maisach.

1979

Takeover of a manufacturer of garden and plant trays and establishment of production in Neuwied.

1978 - 1980

Further development and device adaptation of KW products. Start of licensed production in the USA Use of the motorized Diermayer dampers also for liquid fuels and extension for use as a forced secondary air device for drying chimneys.

1975

First production of large panels for roof, ceilings and walls as a prefabricated basement.

1973

1. energy crisis, resulting in increased use of energy-saving flue gas dampers. This was followed by the development of motor-controlled Diermayer dampers.

1970

Publication of DIN 3388 Part 1 as a standard for thermally controlled flue gas dampers for gas fires. This was also the basis for corresponding regulations in foreign markets.

1968

Adjustment of the production of conventional stones.

1965

Relocation of the company Franz Weber oHG from Munich to a new building in Gröbenzell.

1962

Further development of Diermayer dampers for gas instantaneous water heaters, publication of DVGW – Worksheet G 654 as a technical rule for thermally controlled flue gas dampers – further technical modifications and adaptation to the development of equipment technology.

1952

Start of production of steel-reinforced ceiling beams.

1951

Conversion of the GmbH into Joseph Raab GmbH & Cie. KG. The Strabit stone will not be reintroduced into the production program.

Since 1949

Production of the Diermayer dampers at the Franz Weber company in Munich. Subsequent introduction to the technical rules for gas installations, extension of the dampers to gas-fired heating stoves and introduction of the program in Austria and Switzerland (1960).

1948

Start of plank production

Start of plank production

1946

After considerable efforts, it was possible to restart production.

1945

With the end of the war, Raab also had to stop production.

1939

Approval of the hingeless Diermayer butterfly valve by the German Technical and Scientific Association for Gas and Water (DVGW).

1936

Patented Strabit Stone

Patented Strabit Stone

Patenting of the so-called strabit stone, a heat-retaining pumice bitumen stone produced in a vacuum.

1934

Invention and patent application by Mr. Diermayer for a hingeless, bimetal-controlled butterfly valve for gas-fired instantaneous water heaters, manufacture and sale of the “Diermayer butterfly valves”. Approval of this flue gas damper by various gas plants in Germany.

1921

For the time being, a semi-automatic machine is used for stone production. Until now, it was still made by hand.

1912

Transition from limestone to cement alluvium. Conversion of the sole proprietorship into a limited liability company.

1910

The company grinds pumice stone for chemical applications for the first time, thus expanding its product range.

1903

First production of pumice cement floorboards as a supplement to alluvial stone production.

1898

Signed foundation stone

Signed foundation stone

Today’s Joseph Raab company was founded as Neuwieder Schwemmstein- und Zementwarenfabrik Paul Raab.

1898

Joseph Justus Raab (1839-1918), founder of the company.

Joseph Justus Raab (1839-1918), founder of the company.

“Late at night and early in the morning – long live the alluvial stone industry.”

This was the motto under which Paul Raab founded his company, the “Neuwieder Schwemmstein- und Zementwarenfabrik Paul Raab” in 1898. Since then, the company has continuously developed and gained a leading position in the field of chimney and flue gas systems.

Raab Chronicle

2023

The Raab Group celebrates the 125th anniversary of Joseph Raab GmbH & Cie. KG in Luckenau.

2022

![]()

Die Corporate Identity der Raab-Gruppe erfährt eine Überabreitung, auch hier teht dewr Gruppengedanke im Fokus.

2020

Rolf Wagenfeld, managing partner of the Raab Group, hands over overall sales and marketing management as well as product management to Alexander Root, who becomes deputy managing director in the Raab Group.

Rolf Wagenfeld, managing partner of the Raab Group, hands over overall sales and marketing management as well as product management to Alexander Root, who becomes deputy managing director in the Raab Group.

2015

The Raab Group is expanding its product range through the acquisition of a heat recovery specialist: NET – Neue Energie Technik GmbH from Puchheim near Munich has been active in the heat exchanger business for more than 20 years and brings with it industry expertise in the project planning, design and servicing of heat recovery systems.

2010

Rolf Wagenfeld takes over the management of the Raab group of companies

Rolf Wagenfeld takes over the management of the Raab group of companies

Born in Bremen, he has known the Raab Group since 2001 as a member of the advisory board. From 2007 he held the position of Vice Chairman of the Advisory Board, and since 2009 the position of Chairman of the Advisory Board.

2009

2008

2007

Installation of a new production line for double-walled stainless steel tubes in Neuwied.

The “competence center” for project business and large-scale plants in Luckenau enables the production of technically demanding projects in the industrial and municipal sectors.

Development of the Raab wall, ceiling and roof bushing, the first tested fire protection element developed on the Raab test stand in Neuwied – a true bestseller with record numbers in all sales channels.

2006

Establishment or acquisition of a subsidiary in Hungary

Establishment or acquisition of a subsidiary in Hungary

Approval for the version of the systems EW, DW, EW-Alkon and DW-Alkon called “WPG” especially for wood pellet boilers.

2005

Conversion of J. Raab AG, Luckenau into J. Raab GmbH, Luckenau.

The product range of lightweight chimneys is extended by the LAS-FB multi-shaft.

Expansion of foreign activities.

2004

2003

Product expansion in the area of plaster and mortar products through special solutions. Addition of new lightweight shafts to the flue gas system range.

The DW-Alkon cleaning opening receives the Design+ award at the ISH.

2002

2001

2000

Conversion of J. Raab GmbH & Cie. KG, Luckenau, into J. Raab AG, Luckenau, Germany.

1999

Product line Alkon is supplemented with the double-walled system DW-Alkon.

Certificate for a QM system of the DVGM/VDE of the company Kutzner + Weber according to DIN EN 46001 MPG.

1998

1997

Takeover of Kutzner + Weber, based in Maisach, Germany, and addition of flue gas technology to the product range.

Takeover of Kutzner + Weber, based in Maisach, Germany, and addition of flue gas technology to the product range.

Certificate of the Material Testing Office for a QM system of Joseph Raab GmbH & Cie. KG according to DIN EN ISO 9001.

1993

1991

Start of production at the new plant in Luckenau

Start of production at the new plant in Luckenau1990

1985

Expansion of production to include stainless steel and lightweight chimneys in system construction

Expansion of production to include stainless steel and lightweight chimneys in system construction

In the following years, the area of chimney elements was continuously expanded.

1984

In order to expand further in the area of chimney tops, complementary mortar products were added to the production range.

1983

Adjustment of the production of planters.

Foundation of the company Bekotec which deals with services related to concrete repair.

1979

1975

1968

1952

1951

1948

Start of plank production

Start of plank production1946

1945

1936

Patented Strabit Stone

Patented Strabit Stone

Patenting of the so-called strabit stone, a heat-retaining pumice bitumen stone produced in a vacuum.

1921

1912

1910

1903

1898

Signed foundation stone

Signed foundation stone

Today’s Joseph Raab company was founded as Neuwieder Schwemmstein- und Zementwarenfabrik Paul Raab.

1898

Joseph Justus Raab (1839-1918), founder of the company.

Joseph Justus Raab (1839-1918), founder of the company.

Kutzner + Weber Chronicle

2015

The Raab Group is expanding its product range through the acquisition of a heat recovery specialist: NET New Energy-Technology GmbH from Puchheim near Munich has been active in the heat exchanger business for more than 20 years and brings with it industry expertise in the project planning, construction and servicing of heat recovery systems.

2015

The Airjekt 1 fine dust particle separator is presented at the ISH.

2010

2005

Marketing and further development of the Zumikron fine dust particle separator from the Rüegg company in Switzerland, entry into the distribution of particle separators for flue gas cleaning.

2002

Modernization and adaptation of the flue gas dampers program. Development of further markets abroad.

2001

Integration of Servo-Instuments (SID) in KW license partnership with the Institute for Building Physics (IBP) of the Fraunhofer Gesellschaft in Stuttgart as a scientific partner for the development of special silencer solutions. Start of development work of integrated solutions for the boiler and flue gas industry.

1999

Specialization in the field of flue gas noise, further development of solutions for the market.

1997

Acquisition of the company by the Raab Group.

1989 - 1996

1988

Introduction of the first flue gas silencer program.

1987

Acquisition of the company Servo Instruments Deutschland SID and thus expansion of the flue gas dampers program.

1985

Development and production of KW draught regulators.

1981

Relocation of the company to the new company building in Maisach.

1978 - 1980

Further development and device adaptation of KW products. Start of licensed production in the USA Use of the motorized Diermayer dampers also for liquid fuels and extension for use as a forced secondary air device for drying chimneys.

1973

1. energy crisis, resulting in increased use of energy-saving flue gas dampers. This was followed by the development of motor-controlled Diermayer dampers.

1970

Publication of DIN 3388 Part 1 as a standard for thermally controlled flue gas dampers for gas fires. This was also the basis for corresponding regulations in foreign markets.

1965

Relocation of the company Franz Weber oHG from Munich to a new building in Gröbenzell.

1962

Further development of Diermayer dampers for gas instantaneous water heaters, publication of DVGW – Worksheet G 654 as a technical rule for thermally controlled flue gas dampers – further technical modifications and adaptation to the development of equipment technology.

Since 1949

Production of the Diermayer dampers at the Franz Weber company in Munich. Subsequent introduction to the technical rules for gas installations, extension of the dampers to gas-fired heating stoves and introduction of the program in Austria and Switzerland (1960).

1939

Approval of the hingeless Diermayer butterfly valve by the German Technical and Scientific Association for Gas and Water (DVGW).

1934

Invention and patent application by Werner Diermayer for a hingeless, bimetal-controlled butterfly valve for gas-fired instantaneous water heaters, manufacture and sale of the “Diermayer butterfly valves”. Approval of this flue gas damper by various gas plants in Germany.