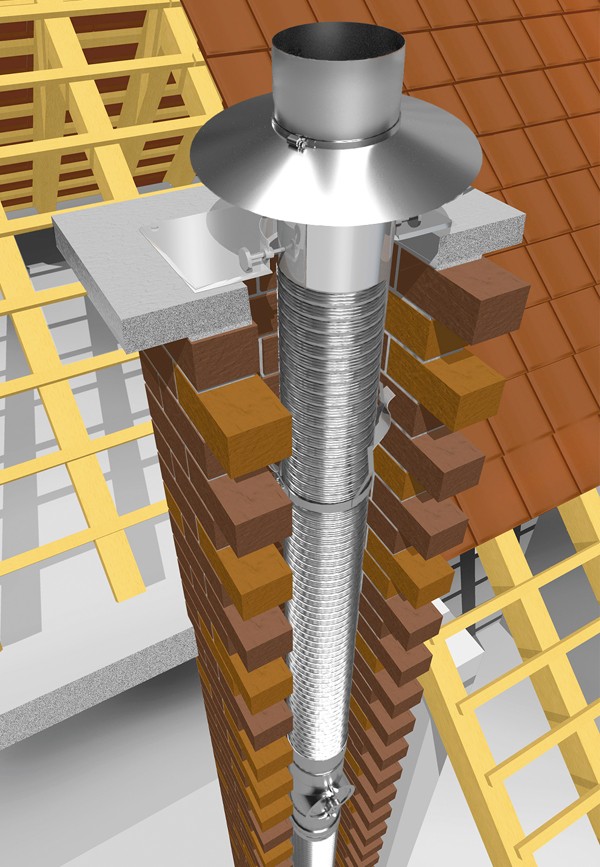

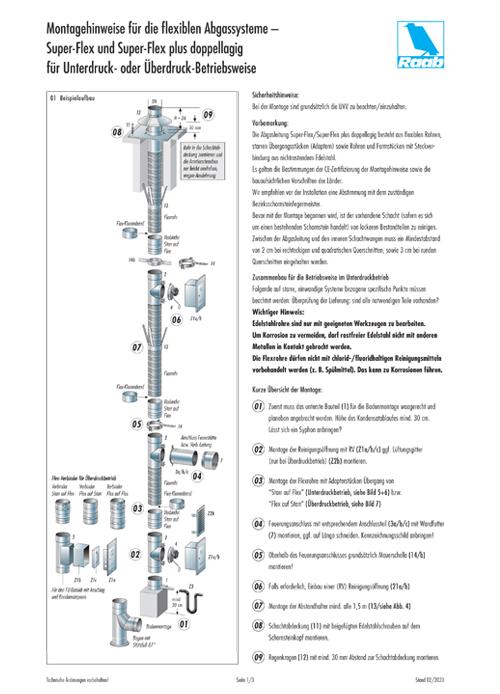

Super-Flex and Super-Flex plus: Extremely flexible, double-layer stainless steel pipes for difficult installation situations

Difficult installation situations such as distortions in the chimney place special demands on the planner, the installer and the material. With the two double-layer flexible stainless steel tubes Super-Flex and Super-Flex plus, we are setting new standards in terms of flexibility and ease of installation.

The special winding technique with clamping on one side allows tight bending radii with high mechanical stability thanks to a wall thickness of 2 x 0.11 mm. This makes Super-Flex and Super-Flex plus easy to install and reliable even in difficult installation situations.

Super-Flex is made of high quality stainless steel type 1.4404 (316L) and has high corrosion resistance and acid resistance. The material for Super-Flex plus is made of the even more acid-resistant stainless steel 1.4539 (904L). Both variants have passed all the necessary corrosion tests and have the CE declaration of performance for flexible metal inner pipes in accordance with EN 1856-2 with voluntary external monitoring in accordance with System 2+.

Both are available in 10 nominal diameters from 100 DN to DN 200. This means that the usually limited installation space in chimney renovations can be used without any problems. The proven plug-connections for combination with the Raab EW rigid fittings ensure quick and easy installation. The flexible pipes are available in standard lengths (10, 30 and 50 m) as well as in individual lengths.

The systems are suitable for all heat generators: from condensing boilers to fireplaces and tiled stoves, gas fireplaces to wood pellet heating systems and wood chip systems. Super-Flex is resistant to humidity up to 200 °C in overpressure operation up to 200 Pa for oil and gas and resistant to soot fires up to 600 °C for solid fuels.

Like all Raab stainless steel pipes, the flexible stainless steel pipes are also “Made in Germany”.

Super-Flex and Super-Flex plus at a glance

| Certification | DOP-No. 0432-CPR-00117-43 |

| T200 P1 WO | 200 °C flue gas temperature, overpressure 200 Pa, humid operation for oil/gas – with EPDM seal |

| T600 N1 D/WG | up to 600 °C flue gas temperature, negative pressure, humid operation for oil/gas, dry operation for oil/gas/solid fuels, soot fire resistant for solid fuels |

Attention: When used with rigid components, observe Raab EW for deviating pressure and temperature resistance!

Material and designs

- Super-Flex made of high-quality stainless steel 1.4404 (316L)

- Super-Flex plus made of the even more acid-resistant stainless steel 1.4539 (904L)

- Wall thickness for both models double-layered 2 x 0.11 mm

- Nominal diameters from 100 – 200 mm available in various gradings

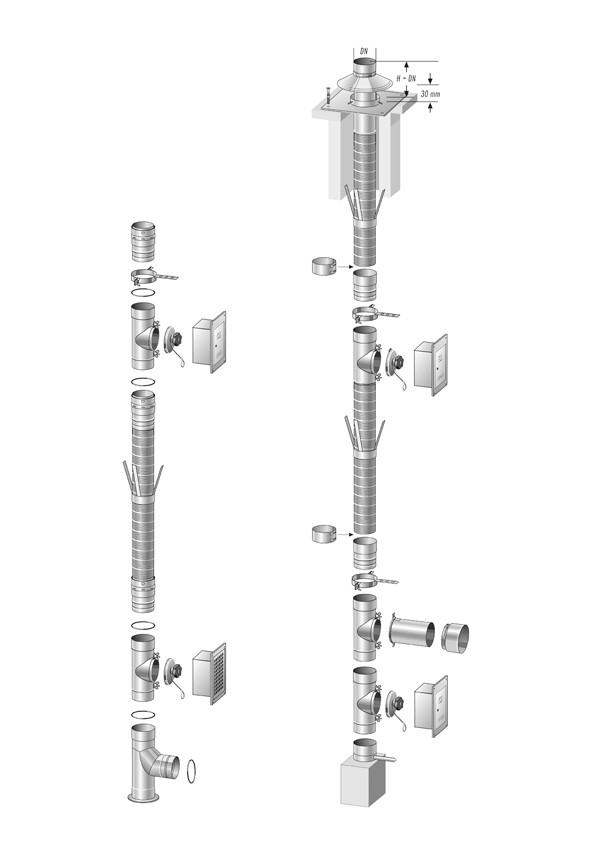

- Practical connention technology: Plug-in connector optionally for positive and negative pressure for easy transition from the rigid fittings to the flexible pipes.

- Delivery forms: The flexible pipes are available in standard lengths of 10, 30 or 50 m or customised.

- High-quality materials: In addition to state-of-the-art production methods, decisive for the longevity of the system and high corrosion resistance.

- High quality: CE declaration of performance for flexible metal inner pipes according to EN 1856-2 with voluntary external monitoring according to System 2+. Certified production according to DIN EN ISO 9001.

- Fireplaces for oil, gas, solid fuels, wood, wood chips, wood pellets

- Low temperature and condensing boilers

- Flue gas temperatures up to 600 °C, soot fire resistant

- Dry and humid (FU) operation mode

- Negative pressure or positive pressure up to 200 Pa with seal

- Single and multiple occupancy

- Room air dependent or room air independent in the shaft (LAS)

- Cross-section reduction of existing installations