DW-Alkon double wall stainless steel flue gas system metal sealing, the innovative

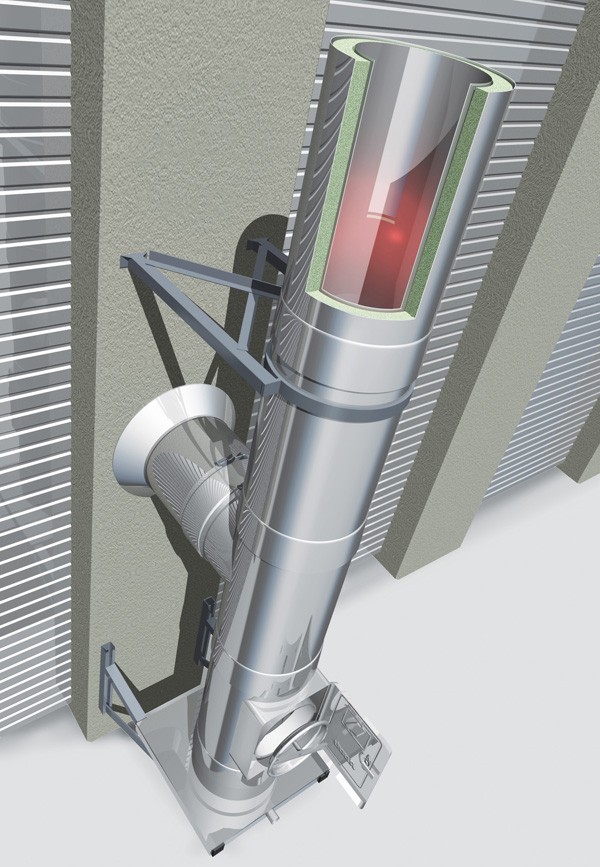

DW-Alkon is a universal double-walled flue gas system with 30 mm heat insulation.

The connection technology with metallic surface seal combines the quality of welded systems with the advantages of light and fast element construction.

The conical plug connection with the ideal taper angle of 2° ensures a pressure-tight connection and at the same time has a high self-locking effect against loosening. The metallic sealing principle without elastomer seals is consistently implemented right down to the cleaning caps and is patented throughout Europe. The 30 mm joint-tight heat insulation guarantees low surface temperatures.

Therefore, DW-Alkon can be used over the entire temperature range from condensing operation up to 600 °C continuous operation in both negative pressure and positive pressure up to 5000 Pa.

The suitability for all types of fireplaces including CHP units, emergency power plants, fuel cells, engine plants allows later retrofitting of the heat generator or retrofitting of flue gas heat exchangers and thus saves investment costs.

A wide variety of fireplaces can be connected, whether chimney or tiled stoves, boilers for oil, gas, wood, wood pellets or condensing boilers for oil or gas. The metallic sealing principle means wear-free operation, minimizes maintenance costs and increases the operational reliability of the heating system.

As a WPG design in material 1.4539 for wood logs, wood pellets and wood chips, the EW-Alkon system is approved for humid operation after any soot fire.

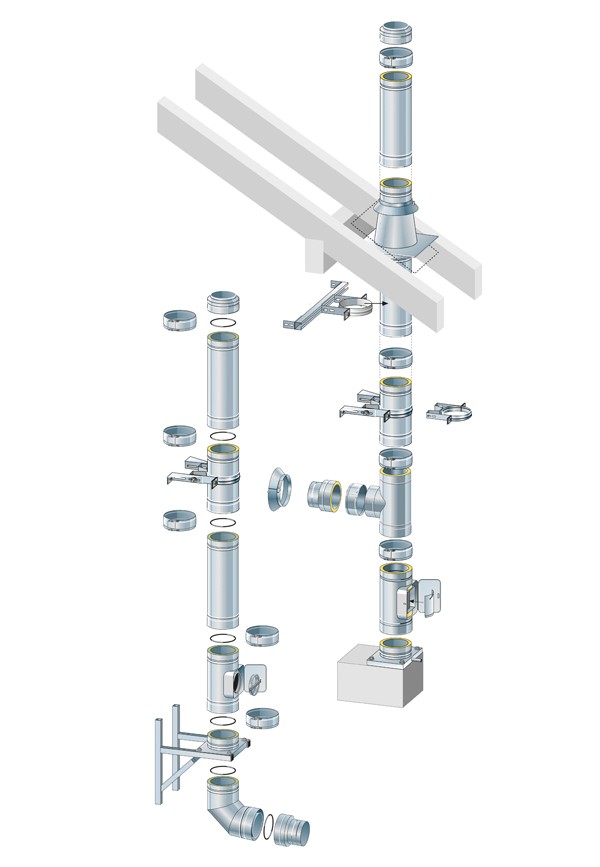

The extensive accessories with shaped parts for almost all situations, fixings, roof ducts, etc. round off the system perfectly.

DW-Alkon at a glance

| Certification | DOP-No. 0432-CPR-00117-21/121 |

| T200 P1 WO | up to 200 °C flue gas temperature, overpressure 200 Pa, humid operation oil/gas |

| T400 N1 WO/DG | up to 400 °C flue gas temperature, negative pressure, humid operation oil/gas, dry operation, soot fire resistant, oil/gas/solid fuels |

| T600 H1 WO | up to 600 °C flue gas temperature, overpressure 5000 Pa, humid operation, oil/gas |

| T600 H1 DG | up to 600 °C flue gas temperature, overpressure 5000 Pa, dry operation, soot fire resistant, oil/gas/solid fuels |

| T600 H1 WG | up to 600 °C flue gas temperature, overpressure 5000 Pa, humid operation, soot fire resistant, oil/gas/solid fuels |

Material and designs

- High-quality stainless steel 1.4404, outer jacket 1.4301

- WPG 1.4539, high temperature material 1.4828 on request

- High-gloss surface, low contamination

- Material thickness inside 0.6 mm, outside 0.6 mm

- 30 mm mineral heat insulation layer

- Inside diameter 80 – 600 mm

- Tubes TIG/laser butt welded

- Moulded parts drawn or welded and passivated using the high-pressure pressing process

- 4 m distance between wall mountings and up to 3 m free overhang

- Up to DN 350 with conical outer shell without clamp band

- From DN 400 with static outer clamp band

- Innovative: The metal-sealing principle is still unmatched by the competition. Numerous patents document the Raab Group’s claim to innovation and future security.

- Design: The cleanout awarded with the Award Design+ and the slim outer shell without clamp band offer an excellent visual appearance.

- Operational reliability: Metal surface seal with 60 mm long cone, can be used wear-free without elastomer seals.

- Speed: Easy to assemble and immediately ready for use. Optimised packaging system

- Flexible: Easily adaptable to difficult conditions due to component diversity.

- High-quality materials: In addition to state-of-the-art production methods, decisive for the longevity of the system and high corrosion resistance.

- High quality: CE declaration of performance with voluntary external monitoring according to System 2+. Certified production according to DIN EN ISO 9001.

- High design flexibility: various finishes available at extra cost (matt, brushed, RAL powder coating or galvanised copper).

- Fireplaces for oil, gas, solid fuels, wood, wood chips, wood pellets, etc.

- Calorific value and low-temperature boilers for oil and gas

- CHP units, emergency power generators, engine systems, heat pumps, fuel cells

- Flue gas and steam pipes for baking ovens, roasting ovens

- Supply and exhaust air lines, silicone-free

- Industrial applications, process heating

- Overpressure up to 5000 Pa and negative pressure operation

- From condensing operation to 600 °C continuous temperature

- Mounting Indoor and outdoor