DW – double-walled stainless steel flue gas system,the classic

The double-walled flue gas system with thermal insulation and classic plug-in connection with external clamp band can be used for all standard fireplaces, including solid fuels, as well as for modern oil and gas fireplaces.

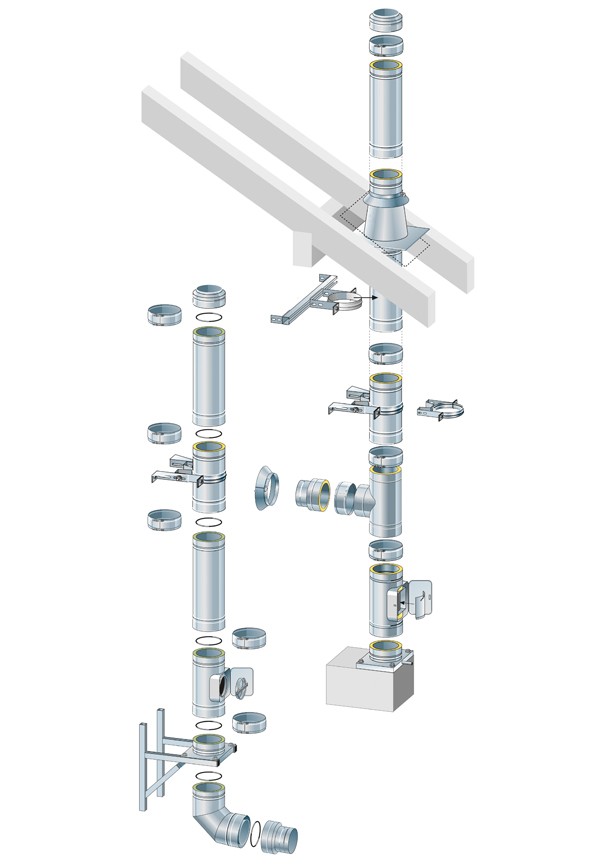

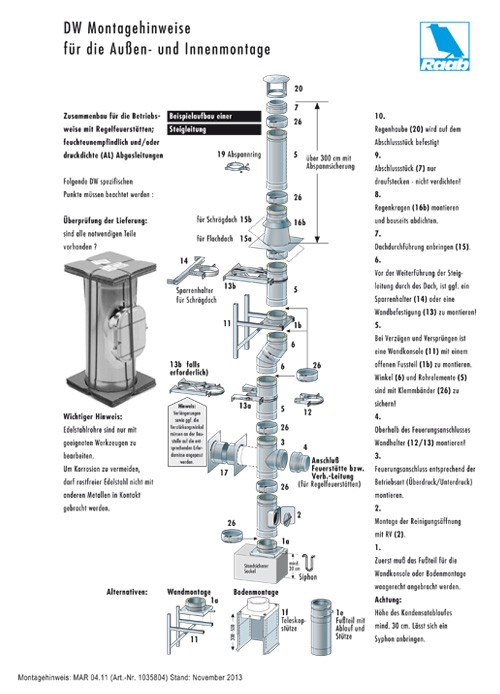

The element construction method allows fast construction progress and the large variety of components permits adaptation to the most difficult assembly situations.

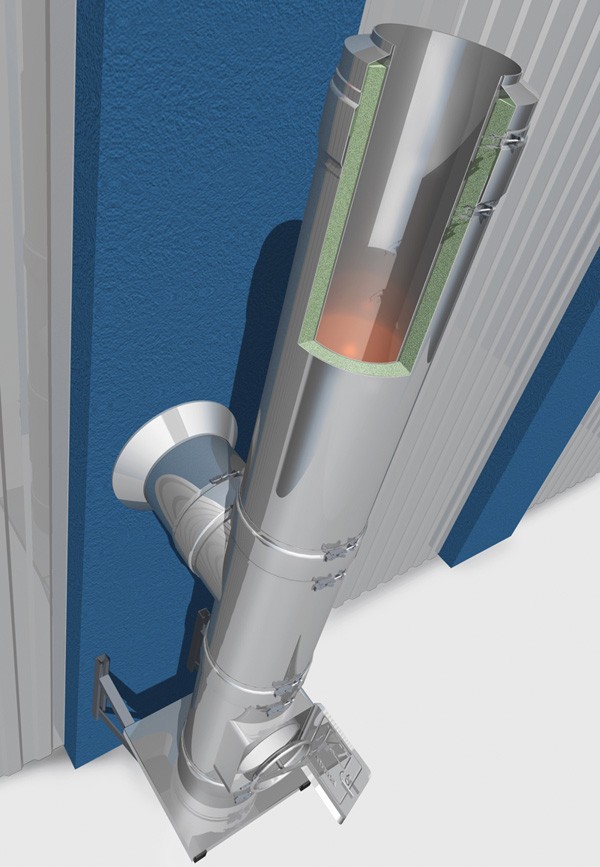

The freely expandable inner shell, together with the 30 mm joint-tight heat insulation, guarantees low surface temperatures. The absence of these thermal bridges prevents cracking noises caused by temperature stresses during rapid heating.

The additional capillary stop incorporated into the outer shell ensures that no moisture can get into the heat insulation from the outside. The statically supporting outer shell with wide quick-release clamp fitting impresses with maximum stability even in difficult installation situations. By means of an easy-to-fit EPDM lip seal, calorific value boilers up to 120 °C flue gas temperature can be connected in positive pressure operation.

The WPG version in material 1.4539 for wood logs, wood pellets and wood chips is even approved for moist operation after a possible soot fire.

The extensive accessories with shaped parts for almost all situations, fixings, roof ducts, etc. round off the system perfectly.

DW at a glance

| Certification | DOP-No. 0432-CPR-00117-20/120 |

| T120 P1 WO | up to 120 °C flue gas temperature, positive pressure 200 Pa, humid operation for oil/gas – with EPDM seal |

| T400 N1 WO | up to 400 °C flue gas temperature, negative pressure, humid operation, oil/gas |

| T600 N1 DG | up to 600 °C flue gas temperature, negative pressure, dry operation, oil, gas, soot fire resistant for solid fuels |

If necessary, see individual components for deviating specifications.

Wall bracket distance 4 m, free overhang 3 m from DN 100 to DN 600

Material and designs

- High-quality stainless steel 1.4404, outer jacket 1.4301

- WPG 1.4539, high temperature material 1.4828 on request

- High-gloss surface, low contamination

- Material thickness inside 0.6 mm, outside 0.6 mm

- 30 mm mineral heat insulation layer

- Inside diameter 100 – 600 mm

- Tubes TIG/laser butt welded

- Moulded parts drawn or welded and passivated using the high-pressure pressing process

- Wide, static outer clamp band as standard

- 4 m distance between wall mountings and 3 m free overhang

- Proven connection technology: The precisely fitting elements with stable clamp band connection have proven their reliability for many many years.

- Capillary stop: Insensitive to humidity from the inside and outside.

- Speed: Easy to assemble and immediately ready for use. Optimised packaging system

- Flexible: Easily adaptable to difficult conditions due to component diversity.

- High-quality materials: In addition to state-of-the-art production methods, decisive for the longevity of the system and high corrosion resistance.

- High quality: CE declaration of performance with voluntary external monitoring according to System 2+. Certified production according to DIN EN ISO 9001.

- High degree of design freedom: various surfaces available at extra cost (matt, brushed, RAL powder coating or galvanized copper).

- Fireplaces for oil, gas, solid fuels, wood, wood chips, wood pellets

- Low temperature and condensing boilers

- Flue gas temperatures up to 600 °C, soot fire resistant

- Dry and humid (FU) mode of operation

- Negative pressure or positive pressure up to 200 Pa with seal

- Single and multiple assignment, connection pipes

Download approvals as PDF file