The challenge

Draught problems can occur in the chimney due to unfavourable weather conditions, an unfavourable positioning of the chimney, a cold flue gas system during start-up or a faulty design of the flue gas system.

In this case, the flue gases are not reliably removed and affect the operational safety of the flue gas system and the fireplace.

In addition, insufficient chimney draught increases emissions and heating costs.

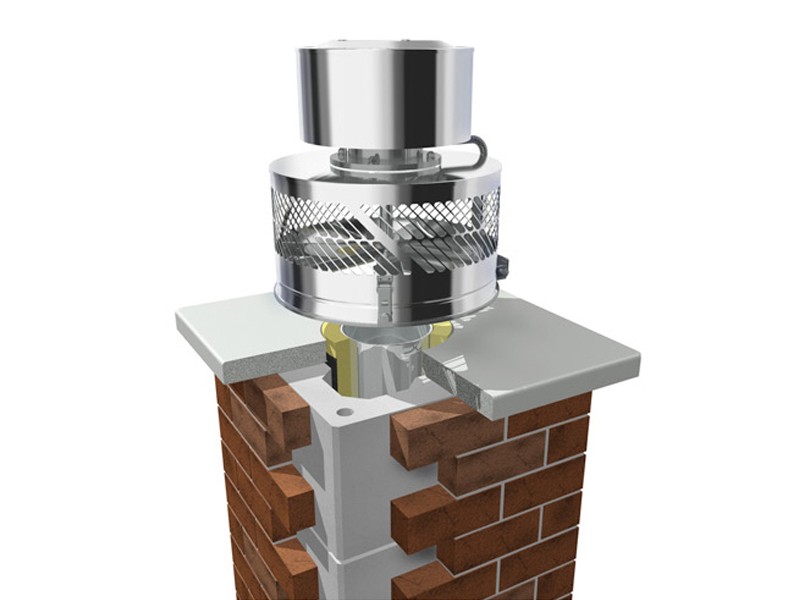

Mounting chimney fan Diajekt

The solution

If the natural draught is too weak for the reasons mentioned above, the DIAJEKT chimney fan ensures reliable and optimum draught in the chimney, which facilitates the lighting of the fireplace or, in extreme cases, makes it possible in the first place.

Due to the constant negative pressure in the flue gas system, combustion is improved, resulting in lower emissions and lower energy consumption.

Flue gas systems and chimneys must be designed in such a way that the negative pressure required for safe flue gas discharge is always present.

This makes the DIAJEKT a safety-relevant component that enables safe acceptance by the chimney sweeper in case of draught problems.

Field of application and mode of operation

The DIAJEKT chimney fan is particularly suitable for fireplaces with negative pressure in the flue gas system, such as:

- Natural draught fireplaces (solid fuel stoves and boilers)

- Fireplaces with sensitive requirements for stable negative pressure (ovens, vapour extractors)

- Multiple occupancies e.g. with gas fireplaces

- Oil and gas fireplaces

- Application in ventilation systems

The DIAJEKT is mounted on the chimney outlet and produces a diagonal ejection of the flue gas due to the special arrangement of the outlet holes.

When the flue gas system is at operating temperature, the chimney fan can be switched off.

The pressure loss is very low and lies within the normal range of measurement fluctuations. The new structure of DIAJEKT offers significant advantages over previous systems.

DIAJEKT is available in three performance classes

| Designation | Nominal width | Power | Negative pressure | Volume flow | Construction height | Weight |

|---|---|---|---|---|---|---|

| RSD 150 | 150 mm | 45 W | 71 Pa | 350 m³/h | 332 mm | 8,3 kg |

| RSD 250 | 250 mm | 115 W | 120 Pa | 1.296 m³/h | 384 mm | 13,6 kg |

| RSD 350 | 350 mm | 350 W | 180 Pa | 3.155 m³/h | 445 mm | 24,5 kg |

DIAJEKT S is available in two performance classes

| Designation | Nominal width | Power | Negative pressure | Volume flow | Construction height | Weight |

|---|---|---|---|---|---|---|

| RSD 150 S | 150 mm | 40 W | 43 Pa | 320 m³/h | 332 mm | 8 kg |

| RSD 250 S | 250 mm | 68 W | 53 Pa | 650 m³/h | 384 mm | 12,8 kg |

- Chimney fan operation only if required. Can also be switched off when the fireplace is in operation, thus minimising the use of auxiliary energy.

- Due to its special design, the DIAJEKT ensures the free outflow of the exhaust gas at standstill.

- Low maintenance and long-lasting, as all electronic components are located outside the aggressive and hot exhaust gases.

- Made entirely of stainless steel (except motor).

- Quick-release fittings on the housing ensure quick and easy maintenance and cleaning; no more loseable screws.

- High stability through the use of plug-in adapters for round flue systems or direct screwing onto the chimney cowl.

- Visually, the unique design blends seamlessly with the stainless steel chimney system.

- Despite its high performance, the DIAJEKT is very quiet in operation and comparatively economical in energy consumption.

- Easy to transport as the cover can be used as a handle.