The Linejekt®

The Linejekt®

Efficient production processes require a constant chimney draught or one that is adapted to the respective production process at all times of the year, whether for the discharge of flue gases or the extraction of process air.

Due to changing weather conditions or also modulating and variable processes in production, conventional flue gases or exhaust air shafts without further flue gas components are unsuitable for this.

With the help of industrial fans and associated control systems, a constant volume of exhaust air can be generated that is adapted to the respective situation. This ensures consistent process quality.

The Linejekt industrial fan was developed for commercial and industrial applications as well as process technology for discharging large exhaust air and exhaust gas volume flows.

Models and mode of operation

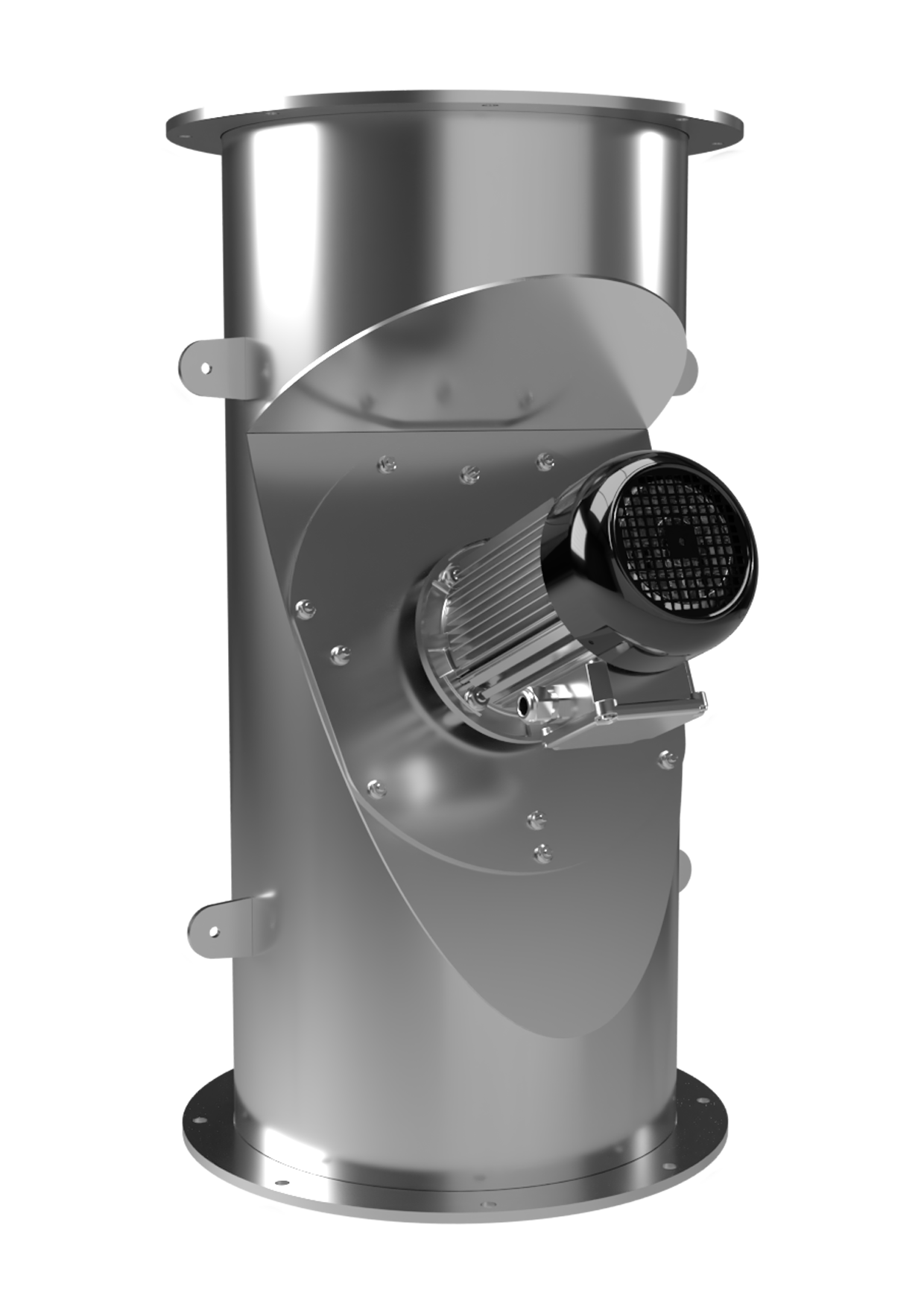

The Linjekt is offered in various sizes from DN 250 to DN 800. Depending on the size, it has a delivery volume of 800 to 17,400 m³/h and can generate negative pressures of up to 1,400 Pa. Gaseous media up to 400 °C can be conveyed. The lineject is continuously adjustable by means of a frequency converter or phase angle control (depending on the motor type) and can thus be adapted to any process. We offer special controls for self-sufficient applications.

All models can be easily integrated into on-site MSR systems. They can be used both indoors and outdoors, in which case the IP54 protection class must be observed; a weather protection canopy for outdoor installation is available as an accessory.

Installation

Mounting is carried out with the mounting accessories matched to the unit and can be carried out in a horizontal or vertical position.

For larger delivery volumes or redundant operation, several Linejekts can be mounted in parallel in the system. The units are matched to the flue gas systems and can be mounted in the system by means of flange connections. Appropriate transitions for various duct and chimney systems can be manufactured on request.

- Consistent process quality during production

- Independence from the natural draught in the chimney or duct system

- Low energy costs

- Ideal for conveying gaseous media

- Extensive accessories

- Indoor and outdoor installation possible

- Low installation costs due to simple installation in the system via flange connection

- Installation in all chimney and duct systems due to factory-made transitions

- Subsequent assembly possible at any time

- Variable adjustment of the output to the process and production requirements

- Low maintenance costs due to low-maintenance components and maintenance-friendly design

- Robust stainless steel construction

- Easy to integrate into on-site MSR systems

- Preprogrammed frequency converter

- Larger delivery volumes or redundant operation possible through parallel mounting

- Use of existing control systems

- Plug and Play on all Raab flange systems

- Adapters to other chimney brands on request

- Material stainless steel

- Size DN 250 to 800

- Delivery volume 800 to 17,400 m³/h

- Negative pressures up to 1,400 Pa

- Flue gas temperature resistant up to 400 °C

- For indoor and outdoor installation