Energy saving and a clean installation room

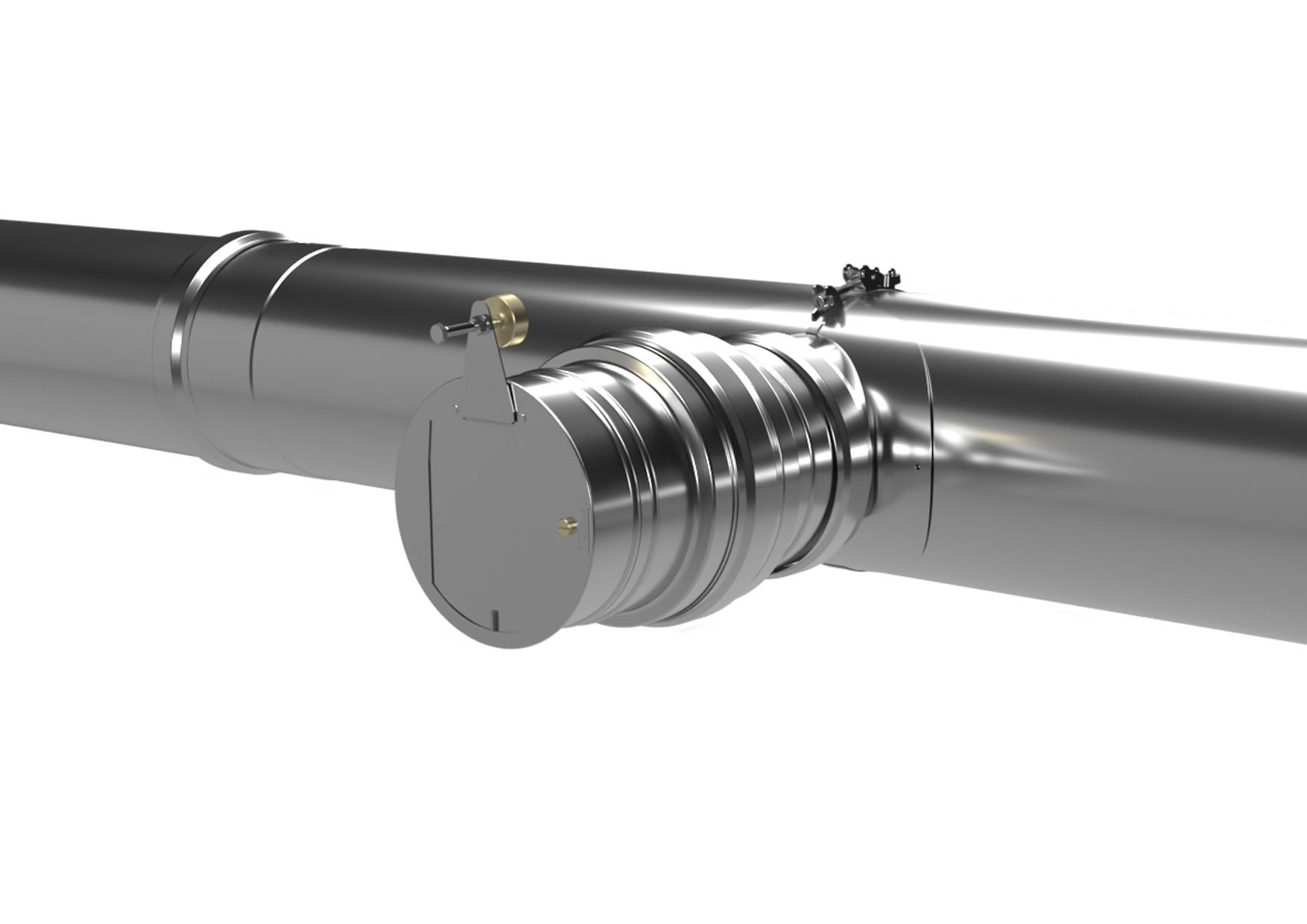

In biomass boilers, ash and soot can be discharged into the installation room via the draught regulator, especially during the start-up phase. To minimize this problem, the filter attachment for precision draught regulators was developed. It can be integrated into new systems as well as into already installed draught regulators via the existing plug-in system.

The filter attachment is plugged into the connection accessory of the draught regulator (available on site or to be ordered separately) and secured with a clamping band. The draught regulator is then mounted on the filter attachment.

Application

The filter attachment is designed for installation as a set or for retrofitting with the Kutzner + Weber’s precision draught regulators. The filter attachment is non-inflammable and can be installed in any fireplace for which a draught regulator can be considered or is already installed.

The filters are available for the draught regulator series Z(UK) 130, Z(UK) 150 (S) and Z(UK) 180. The air group indicated on the draught regulator is reduced by retrofitting the filter attachment.

Cleaning and replacement

The dirty lter can be cleaned with a soft brush under running water. The filter should be cleaned two (occasional heating) to four times (regular heating) per heating period.

After 3 heating periods/years, the filter should be replaced with a new one. The old filter should be disposed of in the residual waste bin. The filter can be replaced in a few easy steps by opening the filter attachment on the clamping band.

Replacement lters are available from Kutzner + Weber:

• Replacement filter for Z(UK) 130, article no. 2123339 2123339

• Replacement filter for Z(UK) 150 (S), article no. 2123340 2123340

• Replacement filter for Z(UK) 180, article no. 2123341 2123341

The sizes correspond to the respective diameters of the draught regulators (130 mm, 150 mm, 180 mm).

The combination of filter attachment and precision draught regulator includes the advantages of a draught regulator and ensures a clean installation room:

✓ Compensation for fluctuations in negative pressure due to weather conditions

✓ Reduction of the dew point and thus later condensate loss

✓ Smooth combustion – clean combustion chamber windows

✓ Lower emissions

✓ Lower fuel consumption – money savings

✓ Active environmental protection with very short payback periods

✓ Minimization of ash and soot discharge into the installation room

✓ For new installation and retrofitting

Here you have the possibility to download the brochures you are interested in as a PDF file.