Chimney fans optimise the combustion

Neuwied, 13 March 2023 – In the wake of the energy crisis, single room fireplaces and biomass heating systems are coming into focus among consumers as an alternative. Renewable energies, in conjunction with modern wood-burning stoves, heating and chimney systems, form an important factor in the energy transition. However, the particulate matter and CO2 emissions of biomass heating systems are viewed critically. The Chimney fans from Kutzner + Weber, a brand of the Raab Group, can provide relief especially for single fireplaces through optimised heating.

Environmentally harmful emissions from burning biomass such as logs and pellets are undoubtedly a problem – especially if they are released unfiltered into the ambient air. When dark clouds of smoke rise into the air from chimneys, this is often due to two things: Either the fuel is not suitable or the stove lacks sufficient combustion air. Especially during the heating phase, both high concentrations of fine dust and visible soot are produced. With retrofittable chimney components, homeowners can optimise the chimney draught and thus reduce the burden on the environment – and save fuel at the same time.

Clean combustion as the basis

The heating phase is particularly important for efficient operation with the lowest possible emissions. Around 80 per cent of emissions and particulate matter are produced in this process. The shorter the heating period, the fewer emissions enter the chimney and the lower the fuel requirement.

Draught problems in the chimney can also occur due to unfavourable weather conditions, an unfavourable positioning of the chimney or a cold flue gas system during start-up. To compensate for this and to reach the operating temperature more quickly through constant draught, chimney fans have proved their worth. There are different models for different applications: from small to large, from single room fireplace to industrial stove. They are simply placed on the chimney mouth and can thus be easily retrofitted in existing buildings.

A fireplace without a guilty conscience

The AirSpeedy chimney fan from Kutzner + Weber was specially developed for stoves and heating inserts in the low output range up to 8 kW. It provides targeted support for the draught, for example during the heating-up phase, when adding wood, in certain weather conditions or if the chimney is not high enough. In addition to promoting efficient burning, the chimney fan also increases heating comfort: nothing smokes back and the windows soot less. The chimney fan operates so quietly that no disturbing noise is produced for the user or neighbours. Operation is virtually at the touch of a button via the supplied remote control.

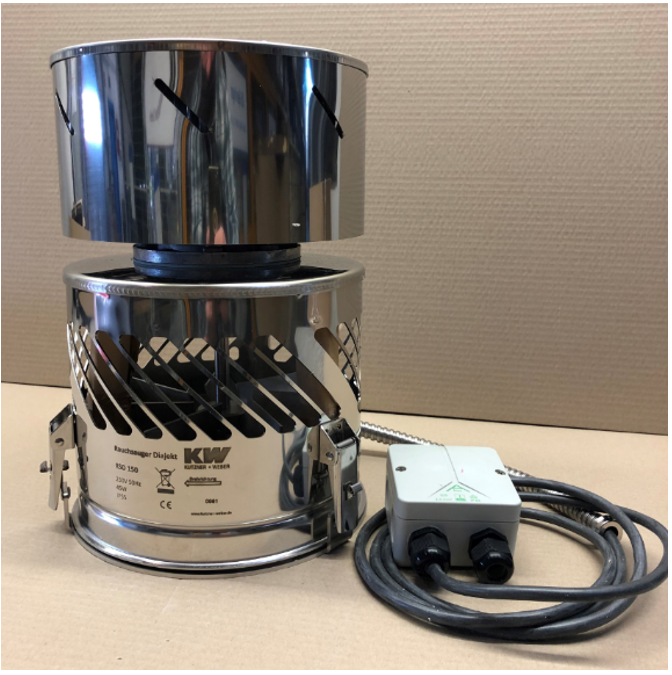

A lack of chimney draught can also reduce the efficiency of larger heating systems such as pellet, oil or gas heating systems. The Diajekt chimney fan is particularly suitable for fireplaces with negative pressure in the flue gas system. These can be so-called natural draught fireplaces, such as solid fuel stoves and boilers, but also oil and gas fireplaces. The Diajekt is also suitable for fireplaces with sensitive requirements for stable negative pressure, such as ovens or vapour extractors. Last but not least, it is also suitable for use in ventilation systems. Another chimney fan model is the Injekt, which was specially developed for pellet and biomass heating systems. Its special feature is that all mechanical and electronic components are located outside the flue gas path.

Chimney fans like the AirSpeedy are an underestimated component: they are hardly noticeable and yet make a valuable contribution to reducing emissions.

The Diajekt chimney fan can be installed in numerous flue gas systems, especially for fireplaces in negative pressure.

Image source: Raab Group